Best Practices for Integrating Cables into Existing Vision Setups

1.Pre-Integration Audit: Assess Compatibility Gaps

Before making physical changes, conduct a thorough audit of the existing system:

Parameter Legacy System Profile New Cable Requirements Compatibility Check

Connector Types M12-D (4-pin) for GigE cameras M12-X (8-pin) for 10GigE Vision Adapter availability (e.g., Turck BSP)

Protocol USB 2.0 (480 Mbps) USB4 (40 Gbps) Backward-compatible controllers

Power Delivery 24V DC via separate PSU PoE++ (Type 4, 90W) Voltage step-down converters

Shielding Foil shielding (60 dB EMI attenuation) Braided shielding (90 dB) Grounding continuity verification

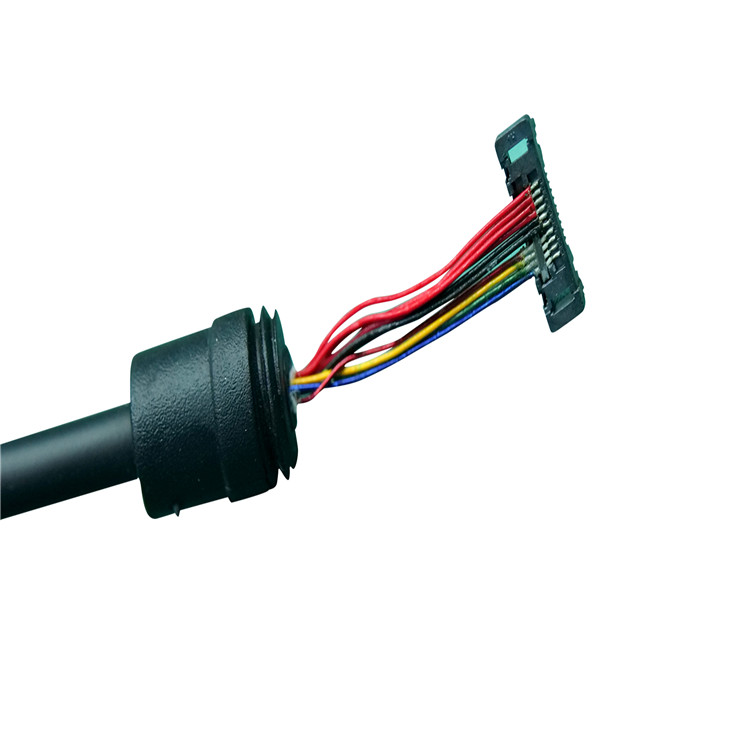

Case Study: At a Bosch assembly line, mismatched M12 connectors caused intermittent signal loss in 8K inspection cameras. The fix? Hybrid M12-D/X couplers with impedance-controlled PCB adapters.

2. Signal Integrity Preservation Techniques

A. Impedance Matching

Legacy Systems: Often use 75Ω coaxial cables (e.g., for analog cameras).

Modern Systems: Require 100Ω differential pairs (e.g., USB4, 10GigE Vision).

Solution: Install impedance-matching baluns (e.g., Belden 1800B) at junctions to prevent reflections.

B. EMI Mitigation

Shielding: Use double-shielded cables (foil + braid) in areas near VFDs or wireless routers.

Routing: Maintain 30 cm separation from high-voltage power lines (per IEC 61000-2-5).

Ferrite Cores: Snap-on ferrite beads (100–500 MHz range) reduce common-mode noise in USB/HDMI cables.

C. Active Signal Conditioning

Equalizers: Extend cable reach without signal degradation (e.g., Microchip EQCO82X for 15m+ USB4 runs).

Repeaters: Fiber-optic media converters (e.g., FLIR Firefly) bridge copper-to-fiber gaps in harsh environments.

3. Mechanical Integration: Stress Relief and Flexibility

Legacy cable trays and conduits often lack the space or flexibility for high-bandwidth cables. Key fixes:

Challenge Solution Product Example

Bend Radius Violations Modular drag chains with 8x radius guides igus E4.1L energy chain

Vibration-Induced Fatigue Strain relief boots + helical wrapping Lapp Ölflex Servo 700 PM

Overcrowded Trays Vertical riser brackets for fiber optics HellermannTyton CableBase

Case Study: A TSMC semiconductor fab reduced cable failures by 70% by retrofitting igus chains in wafer inspection robots.

4. Protocol Harmonization Strategies

A. Hybrid Cable Solutions

Copper-Fiber Hybrids: Run power and low-speed signals over copper while reserving fiber for high-speed data (e.g., Siemon’s LightVerse).

Protocol Converters: Devices like Pleora’s VSI-HD3 bridge Camera Link HS to 10GigE Vision.

B. Software-Defined Reconfiguration

FPGA-Based Controllers: Dynamically adjust termination resistors and equalization settings via software (Xilinx Zynq UltraScale+).

Vision-Specific Middleware: Frameworks like Matrox Imaging’s MIL 10 reduce protocol conflicts in mixed setups.

5. Testing and Validation Post-Integration

Post-integration testing is critical to ensure seamless operation:

Signal Quality Tests:

Eye Diagram Analysis: Verify jitter <0.15 UI and rise/fall times per IEEE 802.3bj.

Bit Error Rate (BER): Target <1e-12 for industrial vision (IEC 61784-5-3).

Environmental Stress Tests:

Thermal cycling (-40°C to 85°C) and 50g vibration sweeps (MIL-STD-810).

EMC Compliance:

Radiated emissions <30 dBµV/m (CISPR 32 Class B).

Tool Recommendation: Keysight’s Infiniium UXR oscilloscope for 110 GHz bandwidth analysis.

6. Future-Proofing for Upcoming Standards

AI-Ready Cables: Deploy Cat 8.1 cables (2 GHz bandwidth) to support edge AI inference workloads.

Modular Connectors: M12-IEC 61076-2-111 connectors allow pinout swaps without recrimping.

Quantum-Secure Links: Pre-integrate QKD-ready fibers (e.g., Toshiba’s MWQ-LD100) for encrypted vision data.